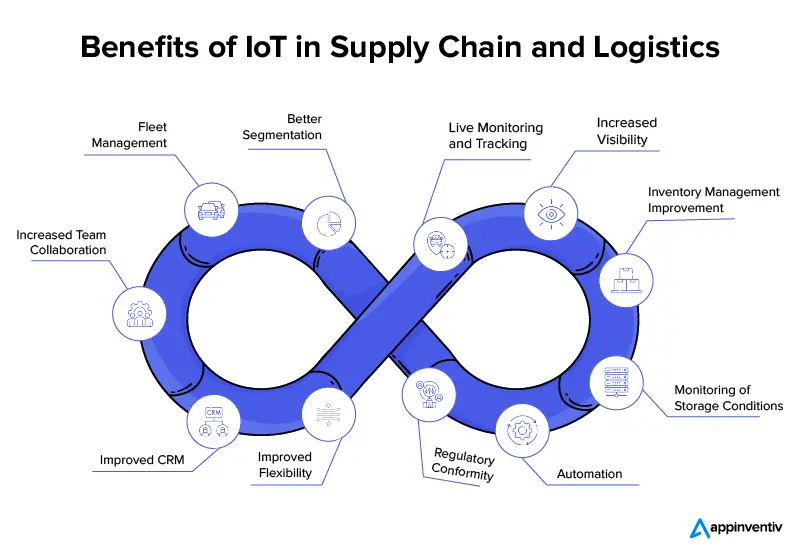

- Benefits of IoT in Supply Chain and Logistics

- Live Monitoring and Tracking

- Increased Visibility

- Inventory Management Improvement

- Monitoring of Storage Conditions

- Automation

- Regulatory Conformity

- Better Segmentation

- Fleet Management

- Increased Team Collaboration

- Improved CRM

- Improved Flexibility

- Applications of IoT in Supply Chain and Logistics

- NJTA – New Jersey Transport Authority

- DHL

- Amazon

- Volvo

- Maersk

- Aker

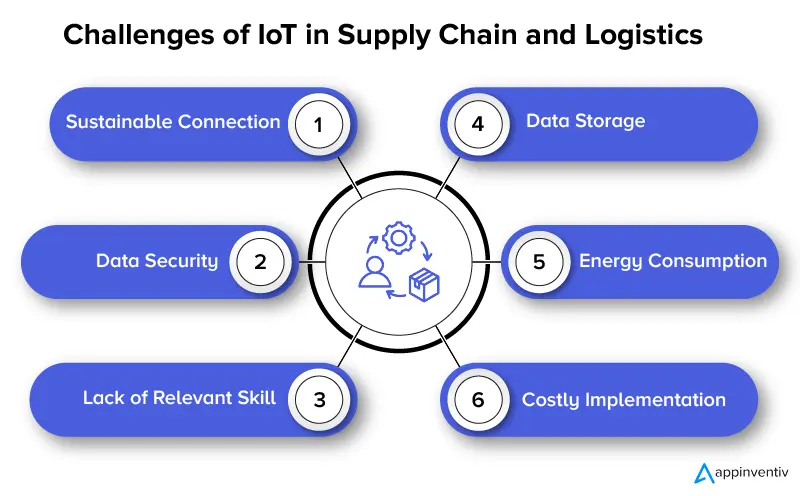

- Challenges of IoT in Supply Chain and Logistics

- Sustainable Connection

- Data Security

- Lack of Relevant Skill

- Data Storage

- Energy Consumption

- Costly Implementation

- How Can Appinventiv Help?

- FAQs

The global supply chain networks are facing unprecedented difficulty and transformation, necessitating the adoption of Industry 4.0 technology to analyze and provide solutions. The Internet of Things (IoT) technology is the most prominent among these solutions, offering a range of advantages to the supply chain industry.

The increasing surge in product demand, worker shortages, lack of critical components and raw materials, etc., are the significant supply chain challenges exposed by the pandemic. It has undoubtedly exacerbated these ongoing issues, yet it is unlikely to be the root cause of all the related challenges. It is essential to identify and address the underlying issues to ensure that supply chains can meet the demands of the global economy.

Deploying IoT devices across different parts of the supply chain — from manufacturing to transportation and distribution center — offers visibility and data collection. Connecting these devices to IoT device management platforms centralizes that visibility and delivers real-time insights where needed most.

As per Statista, the global IoT end-users solutions industry is expected to witness a market share of $1.6 trillion by 2025. Thus, it is the right time to invest in IoT technology for your supply chain and logistic business to leverage the ever-expanding ecosystem.

This article will help you gain insights into how implementing IoT in supply chain and logistics can be beneficial for your business. We will look into the various benefits of IoT in the supply chain and multiple use cases and challenges associated with implementing IoT in logistics and supply chains.

Benefits of IoT in Supply Chain and Logistics

Complex supply chains are becoming connected networks thanks to IoT. IoT device data collection aids in streamlining supply chain operations and enables prompt corrective action to reduce or eliminate losses. In light of that, let’s examine in more detail the advantages of IoT in logistics and supply chain:

Live Monitoring and Tracking

One of the most advantageous aspects of Internet of Things systems is the ability to collect, transmit, and analyze data in real time using specialized sensors. Since you receive the data directly and instantly, these advantageous characteristics make the supply chain and transportation of goods simple to oversee and organize. IoT solutions in supply chain management enable professionals to promptly assess the products in stock and their condition, react quickly to any changes in the status of orders, etc.

Increased Visibility

Every phase of the supply chain, from retail to manufacturing, is affected by IoT. Raw material suppliers use IoT devices to collect information on the variables affecting deliverables’ timely and high-quality availability. Examples include monitoring livestock health for farming, logging operations for forestry, and crop health for agriculture.

Similarly, retailers utilize IoT to improve the accuracy of product collection and boost the effectiveness of material handling. Additionally, they gain from keeping track of products on different shelves for improved inventory control and tracking customer activity for better display and space usage.

Inventory Management Improvement

Inventory must be tracked and controlled to effectively manage a supply chain and a warehouse. IoT in supply chain management, with the help of devices, collects and analyzes stock levels and inventory positions to better manage. With an IoT-enabled inventory system, you can monitor supply levels in real-time, obtain insight into the status of your inventory, make wise business decisions, and prevent product shortages.

Future inventory requirements for the company can be predicted using the data from these systems. You may monitor your product’s physical characteristics, such as leaks, damage, and defective packing. Without any manual effort, IoT makes it simple to update asset information. You get immediate access to crucial details about each delivery, such as the contents of the packages and storage instructions.

Monitoring of Storage Conditions

Environmental sensor tools developed by IoT in transport and logistics allow management to monitor cargo conditions and take immediate action when something changes. For instance, an IoT supply chain system collects information on pressure, humidity, the temperature inside vehicles, and other variables that could jeopardize the integrity of the goods and automatically adjusts the environment accordingly.

Automation

Modern organizations depend heavily on automation to reduce the quantity of physical labor required, the expense of labor, the risk of human error, the speed at which resources are delivered, and various other reasons. The supply chain for manufacturing the necessary automation of this area of management and industrial processes is made possible by IoT. Drones can be used as IoT tools for managing warehouses, or you can build an entire infrastructure that can be operated remotely to track logistics status.

[Also Read: How AI and IoT can transform your business]

Regulatory Conformity

Businesses must adhere to all local legal and regulatory obligations. In terms of managing required documentation and abiding by the law, IoT assists organizations in maintaining regulatory compliance & litigation prevention. An IoT-based system provides a digital audit trail with precise timestamps and quick and accurate reports. This is one of the most significant uses of IoT in logistics.

Better Segmentation

Retailers may establish effective strategies by combining IoT and supply chain management to better understand their products, consumers, and demand. Data gathered during the product cycle aids market research and allows for product segmentation with the target market in mind.

Fleet Management

These kinds of IoT in transport and logistics solutions demonstrate the effects of IoT in logistics. They are frequently incorporated into more intricate systems. Businesses need to gather a lot of real-time data regarding the availability and condition of each vehicle because they can run many vehicles. Tools for fleet management assist businesses in streamlining their overall workflow.

Increased Team Collaboration

Complex value chains frequently degenerate into numerous data silos. Supply chain bottlenecks develop as teams use different sources of information and are not communicating effectively. This is particularly true for businesses using outdated systems with little data analytic capabilities. IoT-based solutions break down data silos by utilizing cloud and data analytics services, providing one version of the truth to all teams along the value chain. It improves teamwork and, as a result, makes problems easier to resolve quickly.

Improved CRM

Software for logistics and Internet of Things supply chains are helpful for customers and management and can be considered as significant use of IoT in logistics. Many businesses employ the benefits of IoT in logistics and offer specialized customer-facing apps to their clientele so they may track the delivery of their orders via GPS and view the status of their orders. It helps build trust and organize the accounts of completed orders when customers can track the delivery progress of their goods to their homes.

[Also Read: How to build a custom CRM system for your business?]

Improved Flexibility

IoT in transport and logistics provides managers with an in-depth understanding of the movement of goods, which aids merchants and supply chain managers in deciding how many units of each product to order. The Internet of Things also decreases the effect of human error by improving shipping, asset tracking, and on-road navigation with high precision.

Applications of IoT in Supply Chain and Logistics

Industry leaders have already presented several IoT use cases in the automotive industry. They have integrated IoT with fundamental supply chain and logistics procedures. Here are a few notable IoT in supply chain examples and uses to consider to understand the use of IoT in supply chain and logistics:

NJTA – New Jersey Transport Authority

The NJTA – New Jersey Turnpike Authority (NJTA) is a good example of IoT in the supply chain to better manage vehicular traffic and enhance road safety. The traffic management operators and the emergency services use the data produced with the aid of IoT sensors to arrive at an accident site more quickly and ease traffic congestion.

DHL

DHL successfully employing IoT-based tools and watches to keep its employees safe at work can be among the list of IoT in logistics examples. DHL’s regional office in Singapore has developed a centralized monitoring system to check staff rest levels, waste movements, break periods, working hours, and weariness. Additionally, this system enables the staff to communicate openly about any potential mistakes or accidents.

Amazon

IoT applications in logistics can be demonstrated with a smart warehouse. A smart warehouse performs routine tasks like labeling, rearranging racks, and using machines and computers. Humans had previously done it.

All of Amazon’s errand-running and heavy-lifting activities are handled by robots. While working alongside the robots, humans concentrate on jobs requiring dexterity and problem-solving. For easier robot navigation, the warehouse floor has QR codes embedded in it. Automation made possible by IoT has allowed Amazon to store 50% more inventory and retrieve it 3x faster. Additionally, the cost of fulfillment is cut by 40%.

Volvo

Volvo is prominent among the IoT in supply chain use cases. The business employs a networked cloud-based system to track the delivery of auto parts from several nations. Volvo tracks car deliveries to its worldwide vendors using the Internet of Things.

Maersk

Maersk is the logistics automation firm to have understood the future of IoT in logistics. It embraced the significance of technology and transparency in the logistics system after realizing that a fix was required for its system since it had grown too complicated and broken.

Maersk uses remote container management to save resource waste and prevent the deterioration of perishable cargo. It uses the RCM (Remote Container Management) technology, which enables monitoring of the humidity and temperature inside the container and the location of chilled containers at any given time. Anytime on board the ship and while in transit, it displays the power connection status.

Aker

Agriculture companies may ensure that raw output is appropriately assessed, packaged, and delivered without sacrificing quality using the IoT in the supply chain, logistics applications, and devices. The Aker firm is a fantastic illustration of how an IoT installation may help a raw material provider. To avoid production loss, Aker rigorously evaluated deep real-time crop observation. Farmers can swiftly assess crop damage caused by insects, disease, and other variables using drones, 3D video cameras, big data technologies, and machine learning.

Challenges of IoT in Supply Chain and Logistics

Many businesses continue to manage deliveries and track assets using traditional legacy systems despite the growing demand for digital transformation. IoT can help organizations address various issues related to business smoothly and efficiently. Having said that, the shifts in business operation methodology bring along some of its challenges. Listed below are some of the challenges you might face while implementing IoT.

Sustainable Connection

Internet service disruption appears to be one of the main dangers to the effectiveness of the Internet of Things in logistics and supply chain management. This is because having optimum bandwidth is of utmost importance when deploying IoT in the supply chain. In order to function properly, connected platforms typically demand a large amount of bandwidth and a powerful server farm. You must set up a reliable network connection with enough speed to enable continuous data collection and transfer to fully utilize all supply chain IoT features.

Data Security

Supply chain managers must concentrate on creating a secure architecture before fully switching all processes to connected platforms. Hacker assaults, breaches, and data processing and storage weaknesses can harm a company’s reputation and increase the likelihood of failure. The good news is that by utilizing the concepts of machine learning and cryptographic hardware monitoring, company management can lessen outside security concerns of IoT in supply chain and logistics while still having secure access to all stored data.

Lack of Relevant Skill

Warehouse employees and truck drivers will need extensive training to adjust to managing networked systems. It takes a lot of effort to describe the security procedures and the rules for utilizing company platforms. Given the absence of specialized IoT training, finding a team with the necessary skills to create a solution tailored to the business is a challenge in and of itself. Supply chain managers should be aware of the fact that recruiting and employing talented workers might take a lot of time, given the global talent shortage in technology.

Data Storage

With effective IoT implementation in supply chain and logistics, the amount of data that sensors collect will increase in a geometric progression, growing by a factor of 10 every working hour. You will therefore need sufficient server power to store and process the given data. Company management will need to develop data governance policies and look for data scientists and analysts to ensure that they draw the appropriate conclusions from IoT-based insights.

[Also Read: A Complete Guide on Data Science & Analytics for Businesses]

Energy Consumption

IoT devices are gadgets designed to function continuously for an extended period. It is very important in industrial IoT systems with thousands of tiny IoT devices. If the battery life of every IoT device is not particularly long, maintaining such a massive IoT system can be extremely time- and money-consuming. Long battery life, low energy communication within systems, and low energy consumption are crucial problems to resolve.

Costly Implementation

Even though one of the objectives of deploying IoT apps is to lower operational expenses, doing so takes significant investments during the initial phase that can be difficult, particularly for young businesses just starting.

Also Read: IoT in Fintech – How It’s Transforming the BFSI Market

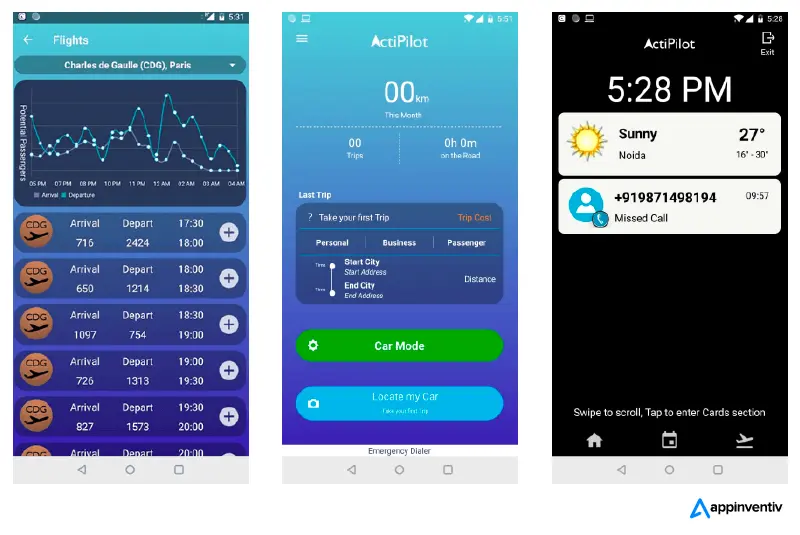

How Can Appinventiv Help?

Realizing the benefits of digital transformation and the necessity for IoT is crucial in improving operational efficiency. But finding skilled personnel from a logistics software development company to implement IoT systems is just as important.

The Appinventiv team can assist you if you’d like to learn more about the potential applications of the Internet of Things, put IoT technology into use, or obtain services for creating an IoT-based system.

The connected network is familiar to our team of IoT developers. We combine speed, security, and scalability into every facet of our IoT application development services because we know how crucial it is to maintain a high level of performance in these areas.

We at Appinventiv have established ourselves as the top provider of IoT application development. We offer Internet of Things solutions that improve productivity and increase profits by streamlining both internal and external procedures.

For instance, for one of our clients, ActiDrive , we developed an IoT-based application that allows drivers to focus on the road while having complete control of mobile devices in a touch-free setup.

Get in touch with our team of experts right away!

FAQs

Q. What are the applications of IoT in logistics and supply chain?

A. A successful logistics company relies on effective communication systems, robust vehicle tracking systems, supply chain monitoring, and the security of the tech systems to manage its operations smoothly. Some of the applications that can accelerate the operations based on collected data are:

- Real-time location tracking

- Warehousing and inventory management

- Fleet management

- Data analytics

- Self driving vehicles

- Drones for deliveries

Q. How does IoT technology improve supply chain efficiency?

A. Locating your goods, tracking their movement, determining where and when they are delayed in transit and planning detours, calculating when they will arrive at a specific location, and keeping track of their storage conditions (temperature, humidity, etc.) are all made much simpler by using IoT in supply chain management. Other benefits of using IoT in logistics and supply chain management also include better segmentation, inventory control, and process automation.

Q. What are the challenges of implementing IoT in logistics and supply chain?

A. The main issue of implementing IoT in logistics and supply chain is data security and privacy because many IoT device manufacturers ignore even the most fundamental security requirements for IoT systems. High maintenance expenses, energy consumption by IoT technology, a lack of IoT implementation skills, connection problems, etc., are some additional difficulties of IoT in the logistics industry.

Route Planner App Development - Costs, Benefits, Features

In the complex world of logistics, where cost-effectiveness and on-time delivery are crucial, route planning is a prominent challenge that can significantly impact the business's bottom line. For fleet managers and drivers alike, navigating the intricate web of roads, traffic, and constantly shifting variables can be an enormous undertaking. This is where route planner apps…

Transportation Management System Development: A Detailed Analysis

In a period of five years, the focus of the supply chain has gradually shifted to making transportation - both inbound and outbound - a streamlined, efficient process. As a response, several transportation management software development solutions have entered the market with the intent of smoothening transport operations and offering network optimizations. Every logistics company…

How Ship Management Software Solves the Modern-Day Challenges of the Logistics Industry

In an era where swift and efficient trade forms the cornerstone of global economies, the logistics industry emerges as its lifeline. With the logistics market expected to grow from $7.98 trillion in 2022 to $18.3 trillion in 2030, there's no denying the sector's monumental impact. Contemporary challenges require sophisticated solutions, and the ship management software…