- Essential Components of Digital Twin Technology in the Energy Sector

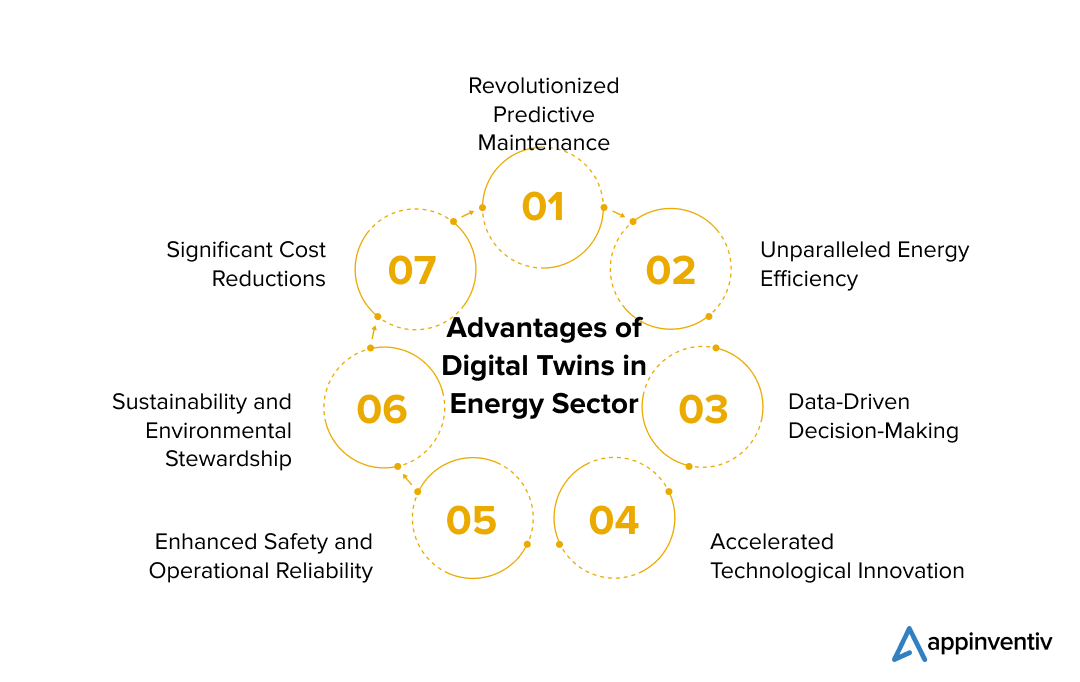

- Benefits of Digital Twin in the Energy Sector: Transforming Energy Operations

- Revolutionized Predictive Maintenance

- Unparalleled Energy Efficiency

- Data-Driven Decision-Making

- Accelerated Technological Innovation

- Enhanced Safety and Operational Reliability

- Sustainability and Environmental Stewardship

- Significant Cost Reductions

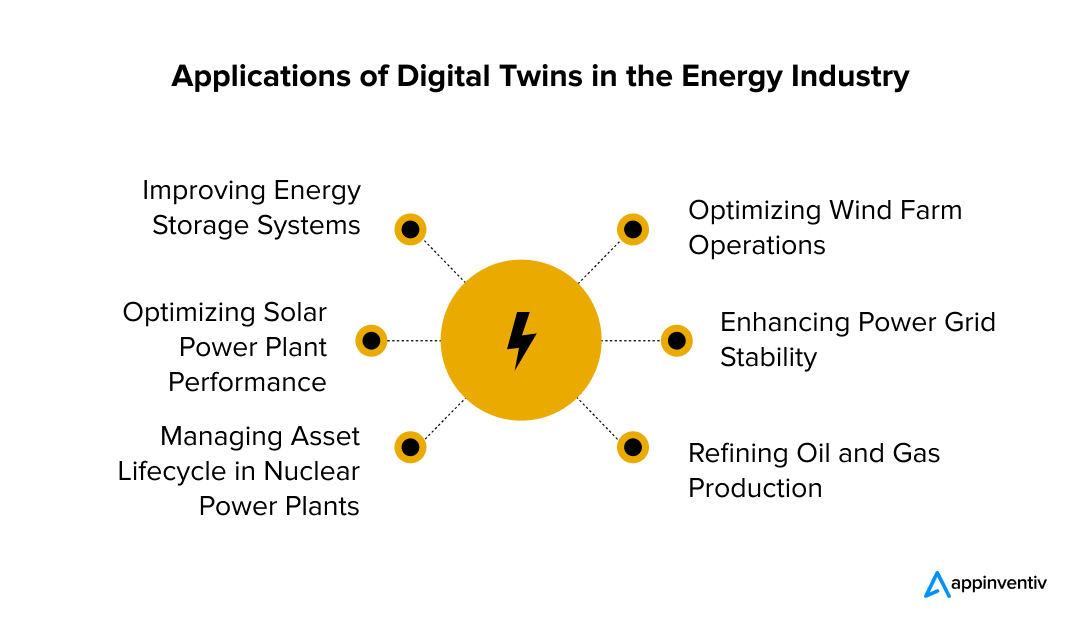

- Use Cases of Digital Twin in the Energy Sector: Revolutionizing Energy Management

- Optimizing Wind Farm Operations

- Enhancing Power Grid Stability

- Refining Oil and Gas Production

- Improving Energy Storage Systems

- Optimizing Solar Power Plant Performance

- Managing Asset Lifecycle in Nuclear Power Plants

- Real-World Examples of How Digital Twins Are Being Used in the Energy Sector

- Future Trends and Developments in Digital Twins

- How Appinventiv Can Empower Your Business with Digital Twin Services

- FAQs

The energy sector, with its expansive growth and evolving demands, encounters a range of challenges, from aging infrastructure to operational inefficiencies and strict environmental regulations. As companies navigate these complexities, the need for innovative solutions becomes increasingly apparent. In this context, the digital twin technology emerges as a game-changing advancement, providing a sophisticated method for tackling these challenges.

By creating virtual replicas of physical assets, systems, or processes, digital twins facilitate real-time monitoring, simulation, and optimization. This technology not only enhances operational efficiency and anticipates maintenance needs but also supports compliance with environmental standards and promotes sustainable practices. In this way, digital twins offer a comprehensive solution that helps businesses address the sector’s challenges and drive progress effectively.

As per the report of Grand View Research, the global digital twin market size was valued at $16.75 billion in 2023 and is expected to expand at a compound annual growth rate (CAGR) of 35.7% from 2024 to 2030.

In this article, we’ll delve into the intriguing world of digital twins in the energy sector, examining their benefits, diverse applications across the industry, and real-world examples that highlight their transformative impact.

Essential Components of Digital Twin Technology in the Energy Sector

Digital Twin technology is transforming the energy sector by creating virtual replicas of physical assets, processes, or systems. These virtual models enable real-time monitoring, analysis, and optimization, driving significant improvements in efficiency and performance. Here are some key components of digital twin technology in the energy sector:

High-Fidelity Asset Modeling

In energy infrastructure, such as oil rigs or power plants, integrating geospatial data into Digital Twin enhances the accuracy of asset models. For example, in offshore oil drilling, Digital Twin incorporates seabed topography and geological data to simulate the complex interactions between drilling equipment and the seabed.

Additionally, advanced simulations model intricate equipment behaviors, such as detailed thermodynamic models of turbines that replicate the impact of varying operational conditions on efficiency and wear.

Advanced Sensor Networks

Energy facilities, such as wind farms and solar arrays, extensively deploy sensor networks to collect data on equipment performance. Digital Twin energy management leverages this data to monitor individual turbine blades’ vibrations and the efficiencies of solar panels in real-time. This advanced monitoring capability, integral to a solar panel monitoring app, enables precise anomaly detection and proactive maintenance scheduling, enhancing overall energy management.

Moreover, sensors in power transformers or generators provide real-time data on factors such as insulation degradation and temperature fluctuations.

Integration of AI and Machine Learning

Machine learning algorithms analyze historical and real-time data from Digital Twins to predict equipment failures. For instance, in a gas pipeline network, AI-driven predictions can forecast the likelihood of leaks based on historical failure patterns and current sensor data.

AI models integrated into Digital Twins also optimize energy distribution and load balancing. In smart grids, these models adjust the distribution of electricity in response to demand changes and grid conditions.

Real-Time Operational Adjustments

Digital Twins enable real-time adjustments to operational parameters. For example, in a hydroelectric plant, Digital Twins for energy simulate water flow and turbine performance, allowing operators to adjust water release rates dynamically to match energy demand and environmental conditions.

Operators also use Digital Twins to test various operational scenarios without affecting real-world operations. In nuclear power plants, this includes simulating emergency scenarios to refine response strategies and improve safety protocols.

Benefits of Digital Twin in the Energy Sector: Transforming Energy Operations

Adopting digital twins technology can set energy sector companies apart by improving operational efficiency, streamlining asset management, and fostering innovation. Digital twins create virtual counterparts of physical assets, systems, or processes, enabling detailed simulations and analyses.

This approach provides valuable insights into performance, supports informed decision-making, and minimizes downtime. Let’s delve into the realm of digital twin technology to uncover its profound benefits and transformative impact on the energy industry.

Revolutionized Predictive Maintenance

Digital twins empower energy companies to monitor and analyze every aspect of their infrastructure in real-time. This leads to a shift from reactive to predictive maintenance, where data-driven insights predict potential failures before they occur. By addressing issues proactively, companies can dramatically reduce unexpected downtime, extend the lifespan of assets, and significantly lower maintenance costs.

Unparalleled Energy Efficiency

Digital twins facilitate the simulation of various operational scenarios, enabling precise analysis of energy production and consumption patterns. By optimizing these processes, companies can achieve remarkable energy efficiency, reducing waste and operational costs. Moreover, this heightened efficiency contributes to lowering carbon emissions, aligning with global sustainability goals.

Data-Driven Decision-Making

The comprehensive digital representation provided by digital twins allows energy operators to make informed, data-driven decisions. These virtual models enable the testing of multiple strategies and configurations in a risk-free environment, allowing companies to refine their approaches before real-world implementation. This results in more effective strategies, reduced operational risks, and enhanced overall performance.

Accelerated Technological Innovation

Digital twins serve as a powerful platform for experimentation and innovation. Energy companies can rapidly prototype and test new technologies, designs, and materials within the virtual environment, significantly speeding up the development cycle. This ability to innovate swiftly not only reduces time-to-market but also drives the adoption of next-generation technologies that can transform the industry.

Enhanced Safety and Operational Reliability

Continuous monitoring and real-time assessments provided by digital twins enhance the safety and reliability of energy systems. By identifying and addressing potential risks and vulnerabilities early on, companies can prevent accident and ensure a consistent, reliable energy supply. This proactive approach strengthens both workers safety, and operational integrity.

Similarly, digital twins in construction improve project outcomes by offering real-time insights into the status of physical assets. This helps construction teams identify potential issues early, ensuring smoother workflows and enhancing overall safety on-site.

Sustainability and Environmental Stewardship

Digital twins are instrumental in advancing sustainability initiatives within the energy sector. By offering deep insights into energy consumption, waste, and environmental impact, these digital models enable companies to optimize their operations for minimal ecological footprint. This alignment with environmental goals benefits the planet and enhances the company’s reputation and regulatory compliance.

(Also read: How AI, IoT, and AR/VR Technologies are Helping Companies Achieve their Sustainability Goals )

Significant Cost Reductions

The adoption of digital twins translates to substantial cost savings across multiple dimensions. By optimizing asset performance and operational processes, companies can reduce energy consumption, maintenance expenses, and the need for physical prototypes. Additionally, the ability to conduct virtual trials reduces the risks and costs associated with testing new technologies in real-world environments.

These enhancements underline how digital twins are a tool and a transformative force in the energy sector, driving innovation, efficiency, and sustainability at unprecedented levels.

Use Cases of Digital Twin in the Energy Sector: Revolutionizing Energy Management

Businesses leverage digital twins for various purposes, such as enhancing operational efficiency, boosting productivity, and driving innovation. Let’s delve into the diverse use cases of digital twins in the energy sector, highlighting how they offer numerous opportunities for growth and advancement.

Optimizing Wind Farm Operations

Digital Twins are used to create virtual models of wind turbines and entire wind farms. Operators can optimize energy production and reduce wear and tear on equipment by simulating wind patterns, turbine performance, and environmental conditions. The virtual models allow for predictive maintenance by identifying potential issues before they occur, thus minimizing downtime and extending the life of the turbines. Additionally, Digital Twins help in designing more efficient turbines by testing different configurations in a simulated environment.

Enhancing Power Grid Stability

Maintaining a stable power grid is crucial in the energy sector. Digital Twins of power grids are employed to monitor real-time operations and predict the impact of fluctuations in demand and supply. These virtual models simulate the entire grid infrastructure, including substations, transmission lines, and distribution networks.

By analyzing data from these models, operators can forecast potential blackouts, optimize load distribution, and quickly respond to faults. This proactive approach ensures a more resilient and reliable power grid.

Refining Oil and Gas Production

Oil and gas companies use Digital Twins to model the entire production process, from exploration to extraction and refining. These virtual models replicate the behavior of reservoirs, drilling equipment, and refining processes. Operators can optimize production rates and enhance safety by simulating different scenarios, such as changes in reservoir pressure or equipment malfunctions.

Digital Twins also supports real-time decision-making during drilling operations, allowing adjustments to be made on the fly, improving efficiency, and reducing costs.

Improving Energy Storage Systems

As renewable energy sources like solar and wind are integrated into the grid, energy storage systems (ESS) become increasingly important for balancing supply and demand. Digital Twins are used to simulate and manage the performance of ESS, such as batteries or pumped hydro storage.

By modeling how these systems interact with the grid and respond to varying energy inputs, operators can optimize storage efficiency, extend battery life, and ensure a stable energy supply even when renewable sources are intermittent.

(Also read: Building Energy Management Systems for Carbon Neutrality)

Optimizing Solar Power Plant Performance

Digital Twins are employed to model solar power plants, including the solar panels, inverters, and grid connections. These models help operators monitor the performance of each component and predict potential failures. By analyzing weather data, Digital Twins can also forecast energy production and optimize the orientation and cleaning schedules of solar panels to maximize efficiency.

Additionally, they enable the simulation of different solar panel configurations to identify the most effective design for specific locations.

Managing Asset Lifecycle in Nuclear Power Plants

Due to their critical operations, nuclear power plants require meticulous asset management. Digital Twins are used to create virtual replicas of nuclear reactors, turbines, and other key components. These models simulate the physical and chemical processes occurring within the plant, allowing operators to monitor the condition of assets in real time.

By analyzing data from sensors and simulations, operators can predict when components will need maintenance or replacement, ensuring that the plant operates safely and efficiently throughout its lifecycle.

Real-World Examples of How Digital Twins Are Being Used in the Energy Sector

Here are some real-life examples of Digital Twins in the energy sector, empowering operators to optimize operations, enhance system performance, and achieve remarkable efficiencies. Let’s delve into these transformative applications!

Siemens’ Gas Turbines

Siemens has implemented digital twins for their gas turbines, used in power generation. These digital twins allow for real-time monitoring and predictive maintenance, which helps in avoiding unplanned downtimes. The data collected through the digital twins also aids in optimizing turbine performance and extending their operational lifespan.

Shell’s Refinery Operations

Shell utilizes digital twin renewable energy for its refinery operations. These digital twins simulate the entire refining process, enabling Shell to optimize production, reduce energy consumption, and minimize emissions. By analyzing data from the digital twins, Shell can also predict and prevent potential operational issues before they occur.

Duke Energy’s Power Grid Management

Duke Energy uses digital twin renewable energy to manage and optimize their power grid. These digital twins for energy provide a virtual representation of the grid’s infrastructure, allowing Duke Energy to simulate various scenarios, predict potential failures, and improve grid reliability. This technology helps in efficiently managing energy distribution and integrating renewable energy sources.

BP (British Petroleum) Oil and Gas Production

British Petroleum (BP) employs a digital twin energy model to monitor and manage their offshore oil and gas platforms. By creating digital replicas of their facilities, BP can simulate and predict the performance of equipment, optimize production processes, and enhance safety. This approach has led to reduced operational costs and minimized the risk of equipment failure.

Challenges in Implementing Digital Twins with Their Potential Solutions

Challenges in Implementing Digital Twins with Their Potential Solutions

Let’s delve into the challenges of digital twins in the energy sector, particularly the ethical considerations businesses face when adopting this technology. This includes concerns related to data privacy, consent, and the potential for increased inequality. As companies leverage digital twins to boost operational efficiency and predictive maintenance, navigating these ethical issues is crucial for ensuring responsible and equitable implementation.

Challenge

Digital twins require high-quality, real-time data to function effectively. Inconsistent or outdated data can lead to inaccurate simulations and predictions, affecting decision-making processes.

Solution

Implement automated data validation and cleansing processes to ensure data accuracy and consistency. Regularly update data sources and establish real-time data feeds to maintain the relevancy of information used in digital twins.

Challenge

High implementation and maintenance costs can be a barrier. Developing and managing digital twins in the energy industry involves significant investment in technology and expertise, which can be prohibitive for some organizations.

Solution

Start with a phased implementation approach, focusing on critical systems first to demonstrate value and achieve quick wins. Explore cloud-based solutions and software-as-a-service (SaaS) options to reduce upfront costs and benefit from scalable, pay-as-you-go models.

Challenge

Integrating digital twins in the energy industry into existing infrastructure can be complex. Many energy systems have legacy systems that may not be compatible with new digital twin technologies.

Solution

Adopt an incremental integration strategy, where digital twins are gradually introduced alongside existing systems. Use middleware and APIs to facilitate communication between legacy systems and new technologies, ensuring smoother integration.

(also read: Legacy Application Modernization Strategy: A Comprehensive Guide to Revitalizing Your IT Infrastructure)

Challenge

Security and data privacy concerns are heightened with digital twins in the energy industry. The extensive data collection and real-time monitoring involved can expose organizations to cyber threats and data breaches.

Solution

Implement robust cybersecurity measures, including encryption, access controls, and regular security audits. Develop and enforce comprehensive data privacy policies to protect sensitive information and comply with regulatory requirements.

Challenge

There is often a lack of skilled personnel who can develop, manage, and analyze digital twins in the energy sector. The specialized nature of this technology means that finding and retaining qualified talent can be challenging.

Solution

Invest in training and development programs to upskill existing employees and attract new talent. Collaborate with academic institutions and industry partners to create a pipeline of skilled professionals and stay updated with emerging trends and best practices in digital twin technology.

Future Trends and Developments in Digital Twins

The future of the energy sector is being transformed by the advent of digital twin technology. With advancements like quantum computing, edge computing, etc. digital twins will enhance operational efficiency, predictive maintenance, and decision-making processes in energy management. These innovations are paving the way for a more intelligent, responsive, and sustainable energy infrastructure, unlocking new possibilities for optimizing performance and reducing operational costs.

Environmental Impact Modeling

As sustainability becomes a global priority, digital twins in the energy sector will be used to model and mitigate environmental impacts. Future developments will include digital twins that simulate environmental changes, resource consumption, and ecological impacts. This will help organizations develop more sustainable practices, optimize resource usage, and predict environmental consequences of their activities.

Quantum Computing for Complex Simulations

Quantum computing holds the potential to enhance the computational power of digital twins in the energy industry. Future digital twins will leverage quantum computing to perform complex simulations and optimizations that are currently beyond the capabilities of classical computers. This will enable more accurate and comprehensive modeling of intricate systems and processes.

Cross-Domain Integration

Digital twins in the energy industry will increasingly integrate data and insights across different domains and industries. This cross-domain integration will provide a holistic view of complex systems, enabling better coordination and synergy between various sectors.

For example, a digital twin of a smart factory might integrate data from supply chain logistics, energy management, and production processes to optimize overall performance.

Autonomous Digital Twins with Edge Computing

With the rise of edge computing, digital twins will become more autonomous. Edge devices will process data locally, reducing latency and enabling faster responses. Autonomous digital twins will be capable of making real-time adjustments and decisions based on localized data, reducing the need for central processing and improving operational efficiency.

How Appinventiv Can Empower Your Business with Digital Twin Services

The impact of digital twin in the energy sector is profound, creating unprecedented opportunities to drive innovation and boost operational efficiency. As a leader in digital transformation services, we offer extensive experience and expertise to guide you through this transformative field.

Whether you aim to enhance predictive maintenance, optimize asset performance, or simulate energy systems for strategic planning, our team is ready to provide customized solutions to meet your unique needs.

Our approach integrates advanced solutions with seamless design, ensuring that custom digital twin platforms not only meet but exceed industry standards. By partnering with an energy development company like Appinventiv, you gain access to a wealth of knowledge, creativity, and a steadfast commitment to excellence, positioning you at the forefront of digital twin technology in the energy sector.

Connect with us to unlock the potential of digital twins, drive innovation in your operations, and achieve superior results with cutting-edge solutions.

FAQs

Q. How does digital twin technology work?

A. Digital twin technology creates a virtual replica of a physical object, system, or process, allowing real-time monitoring and analysis. It works by integrating data from sensors and other data sources to mirror the physical counterpart’s behavior and state.

This replica can simulate, predict, and optimize the physical entity’s performance and can be used for monitoring, troubleshooting, and improving operations. For instance, in manufacturing, digital twins can simulate equipment performance under various conditions to predict maintenance needs and enhance efficiency.

Q. What is the future of digital twins in the energy sector?

A. The future of digital twins in energy is promising, with potential to revolutionize the sector by enhancing efficiency, reducing costs, and improving decision-making. They can simulate and analyze energy systems, optimize performance, and predict equipment failures.

For example, in power generation, digital twins can model entire plants to optimize operations and maintenance schedules. They can also play a crucial role in integrating renewable energy sources by simulating grid behaviors and improving energy management. As technology advances, digital twins will likely become more sophisticated, offering deeper insights and enabling more proactive management of energy systems.

Q. What is digital energy?

A. Digital energy refers to the integration of digital technologies into energy systems to enhance their efficiency, flexibility, and reliability. It involves using digital tools and data analytics to monitor, control, and optimize energy production, distribution, and consumption.

This includes technologies like smart grids, IoT sensors, and advanced analytics that enable real-time data collection and decision-making. Digital energy aims to create more efficient and sustainable energy systems by leveraging data-driven insights and automation to improve performance and adapt to changing energy demands.

10 Use Cases and Benefits of Adopting Digital Twins in Retail

Retail is a vibrant arena, full of opportunity but fraught with challenges. As consumers become more demanding and competition gets fierce, retailers face mounting pressures. From unpredictable consumer demands and ever-changing market trends to supply chain disruptions and the need for personalized customer experiences, there is so much to grapple with. It is a juggling…

Exploring the Impact of Digital Transformation on the Pharma Industry

Digital transformation today is shaking things up in the pharmaceutical world. You might be wondering, What’s the big deal? Well, think of it as the tech revolution for pharma—a game-changer, reshaping everything from drug development to clinical trials and patient interactions. With innovations like machine learning, artificial intelligence, and big data analytics, the industry is…

Automotive Digital Transformation - Benefits, Use Cases and Challenges for Modern Businesses

With qualitative products, customers have shifted their focus towards the experiences they receive from you. These spot-on transactional experiences help them build a strong brand perception for your business, making them loyal. And 46% of consumers say they would pay more to purchase from trustworthy brands. Thus, the exceptional customer experience is a key driver…